2025-06-13

Exploring Classy Thin Wall Injection Molds: Revolutionizing Plastic Manufacturing

In the competitive landscape of manufacturing, especially in plastic molding, efficiency and quality are paramount. Enter the classy thin wall injection mold—an advanced solution that has transformed the way manufacturers produce plastic components. These molds are characterized by their ability to create plastic parts with reduced wall thickness, which not only helps in lowering material usage bu

2025-06-13

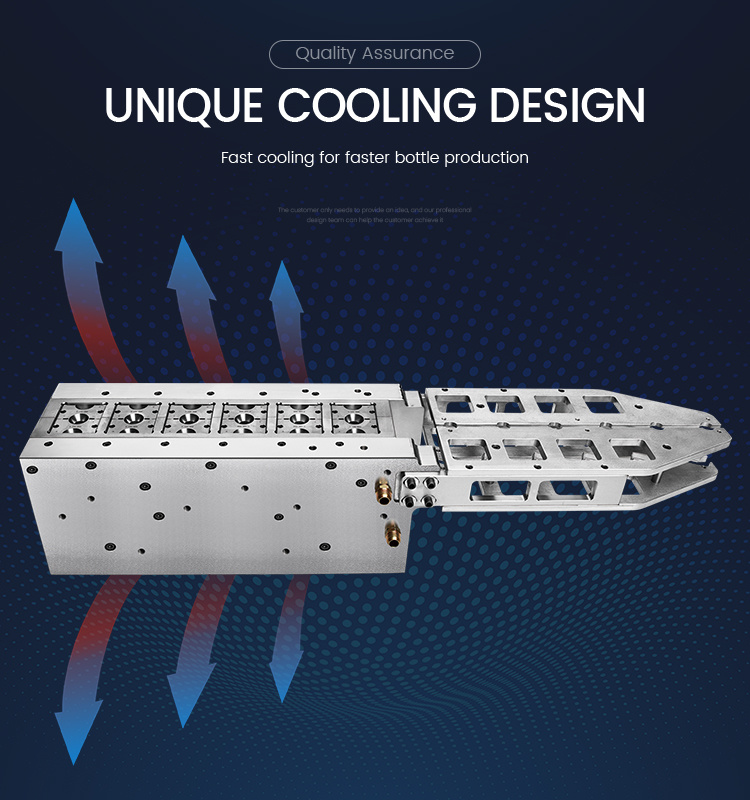

The Evolution of Milk Bottle Production: A Look at Blow Moulding Techniques

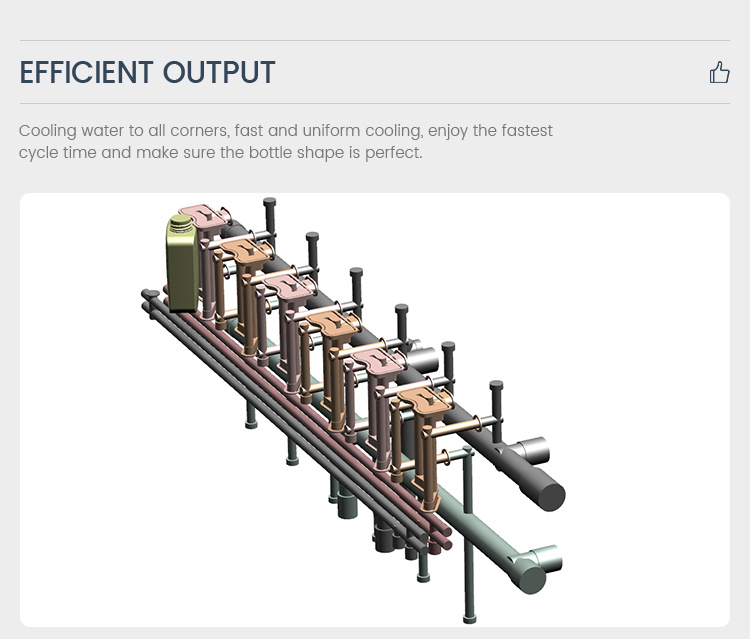

Discover how the milk bottle blow mould with deflashin technique revolutionizes packaging efficiency and quality.

2025-06-12

The Benefits of Investing in Fancy Aluminum Injection Molds: A Comprehensive Guide

The Benefits of Investing in Fancy Aluminum Injection Molds Table of Contents 1. Introduction to Aluminum Injection Molding 2. Why Choose Fancy Aluminum Injection Molds? 2.1 Enhanced Precision and Quality 2.2 Cost-Effectiveness in the Long Run 2.3 Improved Production Efficiency 3. How Fancy Aluminum Injection Molds Compare to Other Materials 3.1 Aluminum vs. Steel Molds 3.2 Performance of Aluminum

2025-06-11

Understanding Durable Precision Injection Molds: Key Insights for the Manufacturing Industry

In the realm of manufacturing, particularly within the domain of plastic molding, the importance of durable precision injection molds cannot be overstated. These molds are essential tools utilized in the injection molding process, wherein molten plastic is injected into a mold cavity to create various plastic parts. The precision in their design and durability directly affects the quality of the f

2025-06-10

Unlocking Efficiency: The Role of Advanced Prototype Plastic Molds in Manufacturing

Unlocking Efficiency: The Role of Advanced Prototype Plastic Molds in Manufacturing Table of Contents 1. Introduction to Advanced Prototype Plastic Molds 2. Understanding Prototype Plastic Molds 3. Benefits of Advanced Prototype Plastic Molds 4. Technological Advancements in Mold Design 5. Optimizing Manufacturing Processes with Plastic Molds 6. Applications of Plastic Mol

2025-06-09

Unlocking the Benefits of Discount Structural Foam Injection Mold Technology

Structural foam injection molding is a specialized plastic manufacturing process that produces lightweight yet durable components. This technique involves injecting a low-density foam into a mold, which expands to fill the cavity, creating a part that is both strong and lightweight. The "discount" aspect of structural foam injection molding often refers to cost-effective solutions that do not comp

2025-06-08

The Crucial Connection Between High-Quality Liquid Silicone Injection Molds and Superior Product Quality Table of Contents 1. Introduction 2. Understanding Liquid Silicone Injection Molding 3. The Importance of Quality Molds in Manufacturing 4. Factors Influencing Mold Quality 5. The Impact of Mold Quality on Product Quality 6. Best Practices for Silicone Mold Manufacturing 7. Case

2025-06-08

The Magic of Milk Bottle Blow Mould with Deflashin: Applications Unveiled

Explore the fascinating applications of milk bottle blow mould with deflashin in modern manufacturing.

2025-06-07

Exploring the Latest Innovations in Polymer Injection Molding

In the realm of manufacturing and processing machinery, particularly in the field of molding and plastic forming, the newest polymer injection mold technology has garnered significant attention. This technique not only enhances the efficiency of production but also ensures high-quality output, making it an essential consideration for manufacturers. Polymer injection molding is a manufacturing proc

2025-06-06

Unlocking the Benefits of Affordable Insert Injection Molds for Enhanced Manufacturing Efficiency

Unlocking the Benefits of Affordable Insert Injection Molds for Enhanced Manufacturing Efficiency Table of Contents 1. Introduction to Insert Injection Molds 2. Understanding Affordable Insert Injection Molds 3. Advantages of Using Affordable Insert Injection Molds 3.1 Cost-Effectiveness 3.2 Enhanced Production Speed 3.3 Versatility in Design 4. Applications of Insert Injection Molds in Various In