Unlocking Efficiency: The Role of Advanced Prototype Plastic Molds in Manufacturing

Time:

2025-06-10

Unlocking Efficiency: The Role of Advanced Prototype Plastic Molds in Manufacturing

Table of Contents

- 1. Introduction to Advanced Prototype Plastic Molds

- 2. Understanding Prototype Plastic Molds

- 3. Benefits of Advanced Prototype Plastic Molds

- 4. Technological Advancements in Mold Design

- 5. Optimizing Manufacturing Processes with Plastic Molds

- 6. Applications of Plastic Molds in Different Industries

- 7. Best Practices for Using Prototype Plastic Molds

- 8. The Future of Advanced Plastic Molding Technology

- 9. Frequently Asked Questions

1. Introduction to Advanced Prototype Plastic Molds

In the fast-paced world of manufacturing, **efficiency** and **product quality** are paramount. Advanced prototype plastic molds have emerged as essential tools for manufacturers striving to enhance their operational capabilities. These molds not only facilitate the rapid development of high-quality products but also significantly reduce lead times and costs. In this article, we explore the intricacies of advanced prototype plastic molds, their benefits, and their transformative role in the manufacturing landscape.

2. Understanding Prototype Plastic Molds

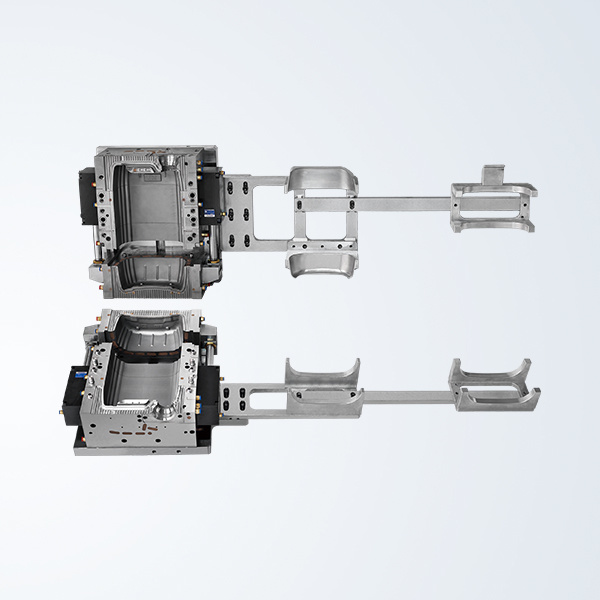

Prototype plastic molds serve as preliminary models for producing plastic components. Unlike traditional molds that are predominantly used for mass production, prototype molds allow for the testing of designs and testing of functionality before full-scale production begins. They are typically made from materials such as aluminum or steel, optimized for quick fabrication and durability.

The Importance of Prototyping in Manufacturing

Prototyping plays a critical role in the **product development cycle**. By utilizing prototype molds, manufacturers can achieve:

- **Design Validation:** Ensure that the product design meets specifications and functional requirements.

- **Cost Efficiency:** Identify potential issues early, reducing the costs associated with redesigns and modifications.

- **Time Savings:** Accelerate the design-to-production timeline, enabling faster product launches.

3. Benefits of Advanced Prototype Plastic Molds

Advanced prototype plastic molds offer several key advantages that contribute to their growing popularity in the manufacturing sector.

Enhanced Design Flexibility

One of the standout features of advanced molds is their ability to accommodate design changes quickly. Manufacturers can test multiple iterations of a product without committing to extensive investments in full-scale production molds.

Improved Product Quality

Using prototype molds allows for precise control over the manufacturing process, resulting in higher-quality end products. This precision leads to fewer defects, enhancing customer satisfaction and brand reputation.

Reduced Production Costs

By identifying design flaws early and allowing for rapid adjustments, advanced molds significantly lower the costs of production. This financial advantage is particularly beneficial for startups and businesses entering competitive markets.

Faster Time-to-Market

In today’s competitive landscape, speed is vital. Advanced prototype plastic molds shorten the development cycle, allowing manufacturers to launch products faster than their competitors. This agility can be crucial for businesses aiming to respond to market demands.

4. Technological Advancements in Mold Design

The evolution of technology has greatly influenced mold design and production methods. Innovations such as **3D printing** and **computer-aided design (CAD)** have revolutionized how prototype plastic molds are created.

3D Printing in Mold Creation

3D printing technology enables the rapid production of molds directly from digital models. This method significantly reduces lead times and allows for intricate designs that traditional manufacturing methods may not achieve.

Computer-Aided Design (CAD) Software

CAD software provides manufacturers with powerful tools to design and simulate molds with high precision. This technology enhances collaboration among design teams and streamlines the prototyping process.

5. Optimizing Manufacturing Processes with Plastic Molds

Integrating advanced prototype plastic molds into manufacturing operations necessitates a strategic approach to optimize processes effectively.

Streamlining Workflow

Optimizing workflow involves mapping out each step, from design conception to mold production. Implementing lean manufacturing principles can further enhance efficiency, minimizing waste and maximizing output.

Utilizing Data Analytics

Data analytics tools can analyze production data to identify bottlenecks and areas for improvement. This information allows manufacturers to make informed decisions about mold design and production techniques.

6. Applications of Plastic Molds in Different Industries

Advanced prototype plastic molds have diverse applications across various industries, enhancing product development and manufacturing processes.

Automotive Industry

In the automotive sector, prototype molds are crucial for producing components like dashboards, panels, and interior trim. These molds allow for rigorous testing of design and functionality before mass production.

Consumer Electronics

The consumer electronics industry relies on prototype molds for creating housings and enclosures for devices. Rapid prototyping ensures that products are not only functional but also aesthetically pleasing.

Medical Devices

In the medical field, precision and safety are paramount. Advanced molds facilitate the development of intricate components for devices, ensuring they meet stringent regulatory standards.

7. Best Practices for Using Prototype Plastic Molds

To maximize the benefits of advanced prototype plastic molds, manufacturers should adhere to several best practices.

Thorough Planning and Design Review

Before fabricating molds, it is essential to conduct a comprehensive review of the design. Engaging cross-functional teams can provide valuable insights and identify potential issues early.

Regular Maintenance of Molds

Proper maintenance of prototype molds ensures their longevity and performance. Regular inspections and cleaning can prevent defects and extend the lifespan of the molds.

Implementing a Feedback Loop

Establishing a feedback loop with stakeholders, including design engineers and production staff, fosters continuous improvement. Regularly reviewing performance metrics can inform future design and manufacturing decisions.

8. The Future of Advanced Plastic Molding Technology

As technology continues to evolve, the future of advanced plastic molding holds exciting possibilities. Trends such as **sustainability** and **increased automation** are set to reshape the industry.

Sustainability in Manufacturing

The push for sustainable practices is driving innovation in mold materials and manufacturing processes. Biodegradable plastics and energy-efficient production methods are gaining traction.

Increased Automation

Automation technologies, including robotics and artificial intelligence, are streamlining the molding process. These advancements enhance precision and reduce labor costs while increasing output.

9. Frequently Asked Questions

What are advanced prototype plastic molds?

Advanced prototype plastic molds are tools used to create plastic components, allowing manufacturers to test designs and functionalities before full-scale production.

What are the benefits of using prototype molds in manufacturing?

The benefits include enhanced design flexibility, improved product quality, reduced production costs, and faster time-to-market.

How does 3D printing impact mold design?

3D printing allows for rapid prototyping and the creation of intricate designs, significantly reducing lead times compared to traditional manufacturing methods.

Which industries benefit from advanced prototype plastic molds?

Industries such as automotive, consumer electronics, and medical devices benefit significantly from advanced prototype plastic molds.

What are the best practices for maintaining prototype molds?

Best practices include thorough planning and design reviews, regular maintenance and inspections, and implementing a feedback loop among stakeholders.

Conclusion

Advanced prototype plastic molds play a pivotal role in modern manufacturing, driving efficiency, quality, and innovation. By embracing the benefits of these molds, manufacturers can optimize their processes and maintain a competitive edge in various industries. As technology continues to advance, the potential for enhanced designs and sustainable practices will further transform the landscape of manufacturing, making advanced prototype plastic molds indispensable in the quest for operational excellence.

RELATED NEWS