Understanding Advanced Polyamide Injection Molding: A Comprehensive Guide

Time:

2025-06-27

---

Advanced polyamide injection mold technology has transformed the landscape of plastic manufacturing, providing a flexible and efficient solution for producing complex parts. Polyamide, commonly known as nylon, is a versatile material favored for its strength, durability, and resistance to wear and tear. Understanding the benefits of advanced polyamide injection molding is essential for anyone involved in the manufacturing process, particularly in the realm of molds and tooling.

One of the primary advantages of utilizing advanced polyamide in injection molding is its exceptional mechanical properties. Polyamide exhibits excellent tensile strength, making it ideal for applications that require robust and resilient components. This material can withstand high levels of stress and strain, which is crucial for parts subjected to harsh operating conditions. Furthermore, polyamide’s inherent resistance to chemicals and temperature variations enhances its suitability in diverse environments, ensuring longevity and reliability.

The injection molding process itself is highly efficient, allowing for the precise production of components with complex geometries. This is particularly beneficial in sectors such as automotive, electronics, and consumer products, where intricate designs are often required. The advanced techniques used in polyamide injection molding, such as multi-material injection and overmolding, enable manufacturers to create more sophisticated parts that combine multiple functionalities within a single component.

Another aspect worth noting is the sustainability factor associated with polyamide injection molding. Many manufacturers are now focusing on eco-friendly practices, and polyamide can be sourced from renewable materials. Moreover, the efficiency of the injection molding process leads to minimal waste generation, aligning with modern sustainability goals and reducing the overall environmental impact.

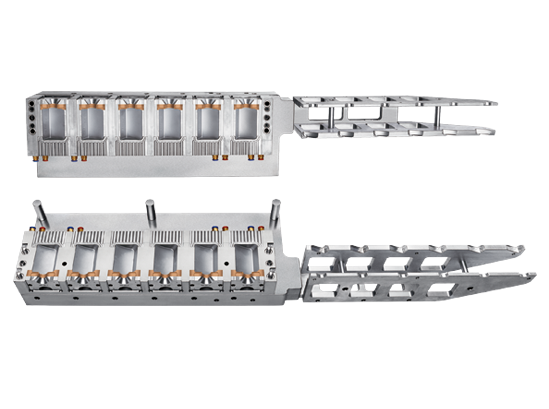

In terms of tooling, advanced polyamide injection molds can be designed to accommodate various production scales, from prototype runs to high-volume manufacturing. The ability to rapidly produce high-quality molds means that businesses can respond quickly to market demands and innovate without significant downtime. Additionally, the advanced CNC machining techniques used in mold fabrication ensure high precision and quality, which are essential for producing parts that meet stringent industry standards.

In conclusion, advanced polyamide injection molding represents a significant advancement in manufacturing technology, offering numerous benefits such as enhanced mechanical properties, production efficiency, and sustainability. As industries continue to evolve, understanding the intricacies of materials like polyamide and the injection molding process will be crucial for manufacturers aiming to stay competitive. Exploring the applications of advanced polyamide injection molds can open new doors for innovation, efficiency, and product development in the ever-changing landscape of manufacturing and processing machinery.

Advanced polyamide injection mold technology has transformed the landscape of plastic manufacturing, providing a flexible and efficient solution for producing complex parts. Polyamide, commonly known as nylon, is a versatile material favored for its strength, durability, and resistance to wear and tear. Understanding the benefits of advanced polyamide injection molding is essential for anyone involved in the manufacturing process, particularly in the realm of molds and tooling.

One of the primary advantages of utilizing advanced polyamide in injection molding is its exceptional mechanical properties. Polyamide exhibits excellent tensile strength, making it ideal for applications that require robust and resilient components. This material can withstand high levels of stress and strain, which is crucial for parts subjected to harsh operating conditions. Furthermore, polyamide’s inherent resistance to chemicals and temperature variations enhances its suitability in diverse environments, ensuring longevity and reliability.

The injection molding process itself is highly efficient, allowing for the precise production of components with complex geometries. This is particularly beneficial in sectors such as automotive, electronics, and consumer products, where intricate designs are often required. The advanced techniques used in polyamide injection molding, such as multi-material injection and overmolding, enable manufacturers to create more sophisticated parts that combine multiple functionalities within a single component.

Another aspect worth noting is the sustainability factor associated with polyamide injection molding. Many manufacturers are now focusing on eco-friendly practices, and polyamide can be sourced from renewable materials. Moreover, the efficiency of the injection molding process leads to minimal waste generation, aligning with modern sustainability goals and reducing the overall environmental impact.

In terms of tooling, advanced polyamide injection molds can be designed to accommodate various production scales, from prototype runs to high-volume manufacturing. The ability to rapidly produce high-quality molds means that businesses can respond quickly to market demands and innovate without significant downtime. Additionally, the advanced CNC machining techniques used in mold fabrication ensure high precision and quality, which are essential for producing parts that meet stringent industry standards.

In conclusion, advanced polyamide injection molding represents a significant advancement in manufacturing technology, offering numerous benefits such as enhanced mechanical properties, production efficiency, and sustainability. As industries continue to evolve, understanding the intricacies of materials like polyamide and the injection molding process will be crucial for manufacturers aiming to stay competitive. Exploring the applications of advanced polyamide injection molds can open new doors for innovation, efficiency, and product development in the ever-changing landscape of manufacturing and processing machinery.

RELATED NEWS