Unlocking Efficiency: The Advantages of China Freeform Injection Molds

Time:

2025-06-20

Unlocking Efficiency: The Advantages of China Freeform Injection Molds

Table of Contents

1. Introduction to Freeform Injection Molds

2. The Advantages of Freeform Injection Molds

2.1 Enhanced Design Flexibility

2.2 Improved Production Efficiency

2.3 Cost-Effectiveness in Manufacturing

3. Applications of Freeform Injection Molds in Various Industries

3.1 Automotive Industry

3.2 Medical Devices

3.3 Consumer Electronics

4. The Technology Behind Freeform Injection Molding

4.1 Materials Used in Freeform Injection Molding

4.2 The Injection Molding Process Explained

5. Challenges and Solutions in Freeform Injection Molding

5.1 Addressing Quality Control Issues

5.2 Innovations in Technology to Overcome Challenges

6. Future Trends in Freeform Injection Molding

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Freeform Injection Molds

In recent years, freeform injection molding has emerged as a revolutionary technique in the field of manufacturing, especially within China. This innovative approach allows for the creation of intricate shapes and components that traditional molds cannot achieve. As industries strive for higher efficiency and quality, understanding the benefits of freeform injection molds becomes essential for staying competitive.

2. The Advantages of Freeform Injection Molds

Freeform injection molds offer several advantages that enhance manufacturing processes, leading to improved product quality and efficiency.

2.1 Enhanced Design Flexibility

One of the most significant advantages of freeform injection molds is their **design flexibility**. Unlike conventional molds that require strict geometric limitations, freeform molds can accommodate complex shapes and intricate designs. This flexibility encourages innovation in product design, allowing manufacturers to create items that satisfy unique consumer demands without compromising quality.

2.2 Improved Production Efficiency

Freeform injection molding allows for **rapid production cycles**, which significantly reduces lead times. The ability to produce multiple components simultaneously enhances throughput, allowing businesses to meet market demands more effectively. Additionally, fewer secondary operations are needed, as products can often be produced ready-to-use, further optimizing efficiency.

2.3 Cost-Effectiveness in Manufacturing

The initial investment in freeform injection molding technology may be higher than traditional methods, but the long-term benefits often outweigh these costs. By producing complex parts efficiently, manufacturers can save on both labor and material expenses. Moreover, reducing waste and enhancing product quality minimizes costs associated with defects and rework.

3. Applications of Freeform Injection Molds in Various Industries

The versatility of freeform injection molds means they can be applied across several industries, each benefiting from the unique attributes of this technology.

3.1 Automotive Industry

In the automotive sector, freeform injection molds are utilized to create lightweight and complex components that improve vehicle performance and fuel efficiency. From intricate dashboard designs to advanced safety features, these molds play a crucial role in modern vehicle manufacturing.

3.2 Medical Devices

The medical industry requires precision and reliability, making freeform injection molds ideal for producing components such as housings for medical devices, surgical instruments, and drug delivery systems. The ability to manufacture small, intricate parts with tight tolerances ensures that medical devices meet stringent regulatory standards.

3.3 Consumer Electronics

Consumer electronics rely heavily on aesthetically pleasing and functional designs. Freeform injection molds allow manufacturers to create sleek and attractive casings for smartphones, tablets, and other electronic devices, enabling them to stay competitive in a rapidly evolving market.

4. The Technology Behind Freeform Injection Molding

Understanding the technology that drives freeform injection molding helps illuminate why it's becoming a favored choice for manufacturers worldwide.

4.1 Materials Used in Freeform Injection Molding

A variety of materials can be used in freeform injection molding, including thermoplastics, thermosets, and elastomers. Each material offers unique properties that can be leveraged to achieve desired characteristics in final products, such as durability, flexibility, and heat resistance.

4.2 The Injection Molding Process Explained

The freeform injection molding process involves several key steps:

1. **Material Preparation**: The chosen polymer is prepared and heated until it reaches a molten state.

2. **Injection**: The molten material is injected into a mold at high pressure.

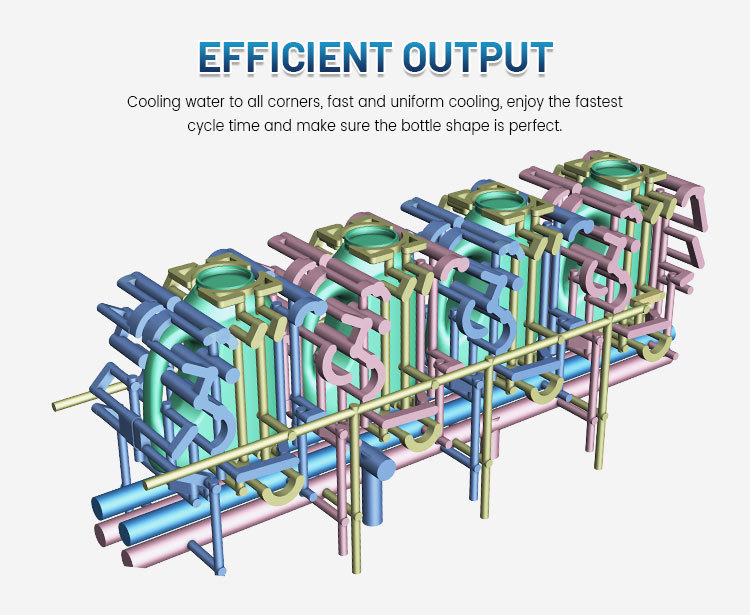

3. **Cooling**: Once injected, the material cools and solidifies, taking the shape of the mold.

4. **Ejection**: Finally, the molded part is ejected from the mold, ready for further processing or assembly.

5. Challenges and Solutions in Freeform Injection Molding

While freeform injection molding presents significant benefits, it is not without its challenges. Understanding these challenges is critical for successful implementation.

5.1 Addressing Quality Control Issues

Quality control can be challenging due to the complex designs often produced with freeform molds. Manufacturers must invest in advanced monitoring systems to ensure that every product meets quality standards. This includes implementing real-time inspection techniques and automated feedback systems to catch defects early in the production process.

5.2 Innovations in Technology to Overcome Challenges

Technological advancements, such as improved simulation software and 3D printing integration, help address quality control issues. These innovations enable manufacturers to predict how materials will behave during the injection process, allowing for precise adjustments to be made before production begins.

6. Future Trends in Freeform Injection Molding

As technology continues to evolve, the future of freeform injection molding looks promising. Key trends include increased automation, the integration of artificial intelligence (AI) for better predictive maintenance, and advancements in sustainable materials. These trends will not only enhance production efficiency but also lead to environmentally friendly manufacturing practices.

7. Frequently Asked Questions (FAQs)

1. What is freeform injection molding?

Freeform injection molding is a manufacturing process that allows for the creation of complex shapes and components using specialized molds, enabling high efficiency and product quality.

2. What industries benefit from freeform injection molds?

Industries such as automotive, medical devices, and consumer electronics benefit significantly from freeform injection molding due to its design flexibility and production efficiency.

3. How does freeform injection molding improve production efficiency?

Freeform injection molding improves production efficiency by enabling rapid production cycles, allowing multiple components to be produced simultaneously, and reducing the need for secondary operations.

4. What materials can be used in freeform injection molding?

A variety of materials, including thermoplastics, thermosets, and elastomers, can be used in freeform injection molding, each offering unique properties suited for different applications.

5. What challenges does freeform injection molding face?

Challenges include quality control issues due to complex designs and the need for advanced monitoring systems. However, innovations in technology are helping to address these challenges effectively.

8. Conclusion

The evolution of freeform injection molds in China has revolutionized the manufacturing landscape, providing companies with the tools needed to enhance efficiency, reduce costs, and produce high-quality products. By embracing this technology, manufacturers can unlock new levels of innovation and remain competitive in a rapidly changing market. As we look to the future, the continual advancements in freeform injection molding promise to further reshape industries, making it an exciting time for manufacturers worldwide.

RELATED NEWS