Unlocking the Potential of Customized Precision Injection Molding

Time:

2025-03-16

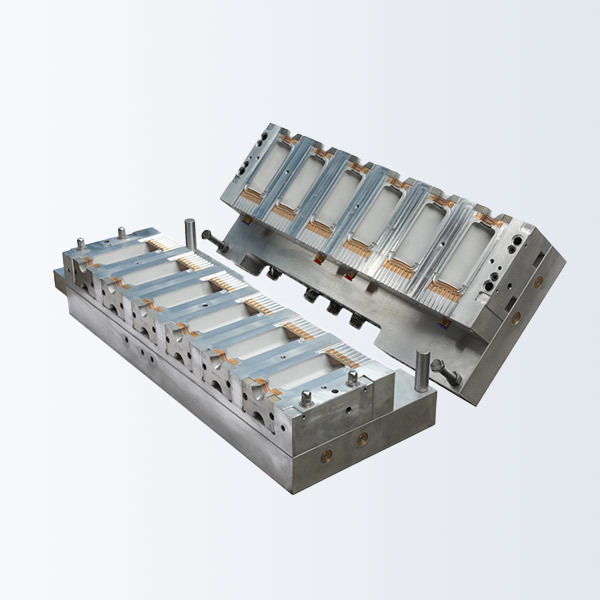

In the manufacturing and processing machinery sector, especially within the realm of molds and plastic forming tools, the significance of customized precision injection mold cannot be overstated. This approach not only enhances production efficiency but also allows for remarkable flexibility in design, ensuring that the final products meet specific requirements and standards.

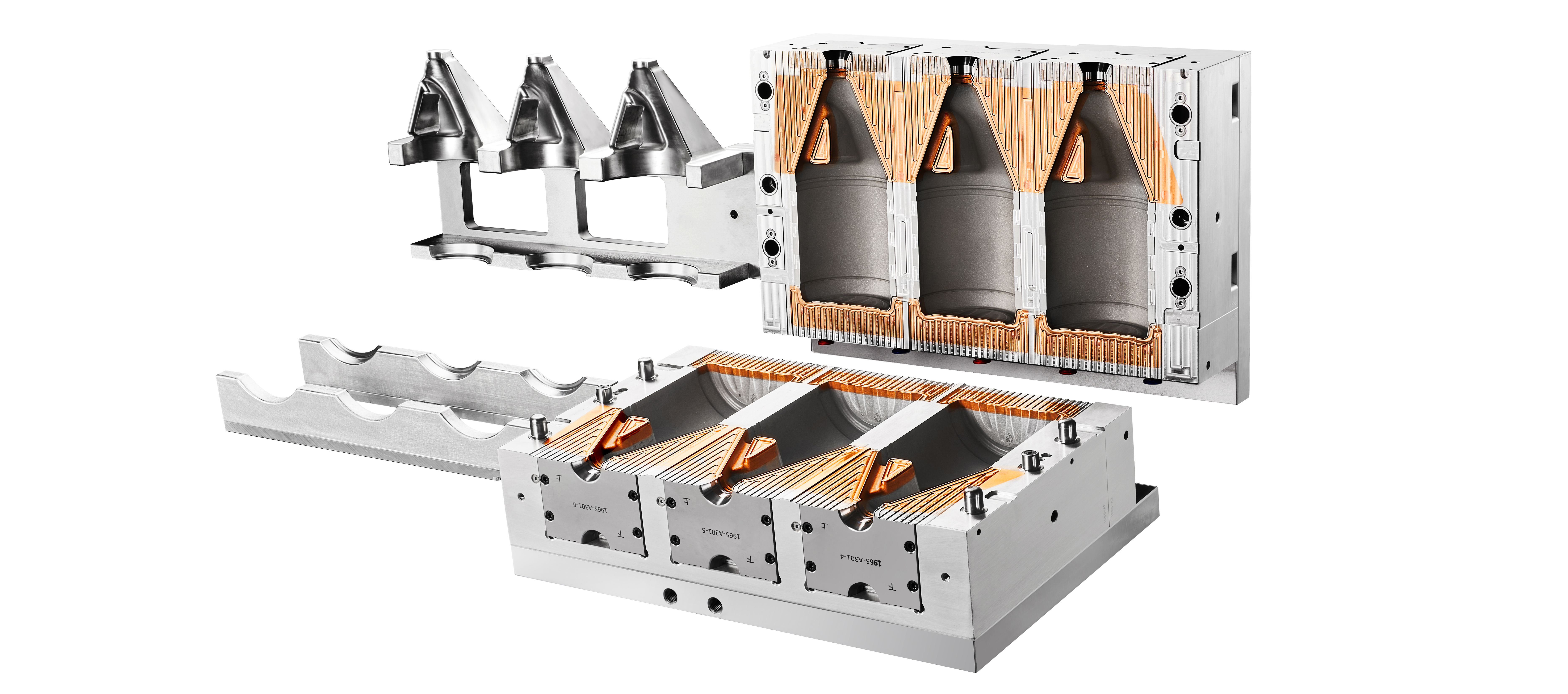

Customized precision injection molding involves creating molds that are tailored to the unique specifications of a project. This means that the mold is designed to produce parts that fit precisely within the desired parameters, thereby improving the overall quality and functionality of the product being manufactured. The process begins with a thorough understanding of the client's specifications, including dimensions, tolerances, and materials required. By closely collaborating with clients, manufacturers can develop molds that are perfectly suited for their intended application.

One of the key advantages of customized precision injection molds is their ability to minimize waste. Traditional manufacturing processes often result in excess materials and inefficiencies. However, by utilizing a finely tuned mold, manufacturers can ensure that every ounce of material is used effectively, leading to cost savings and a reduced environmental footprint. Additionally, precision molding allows for faster production cycles, which is essential for businesses aiming to maintain a competitive edge in today's fast-paced market.

Another important aspect is the versatility offered by customized molds. These molds can be designed for a wide range of applications, from intricate components used in electronics to robust parts required in automotive manufacturing. The ability to create molds that cater to specific industries means that manufacturers can diversify their offerings and adapt to changing market demands more effectively.

Furthermore, the technology behind precision injection molding has advanced significantly over the years. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) has streamlined the mold design and production process. This not only increases accuracy but also shortens lead times, allowing manufacturers to respond more quickly to customer needs.

Customized precision injection molds play a crucial role in the manufacturing process across various industries. By focusing on tailored solutions, manufacturers can achieve higher quality products, reduce waste, and enhance operational efficiency. As the demand for precision and customization continues to rise, investing in this technology is essential for staying relevant in the competitive landscape of manufacturing.

RELATED NEWS