The Ultimate Guide to Best Practices for Using OEM Teflon Injection Molds Effectively

Time:

2025-02-27

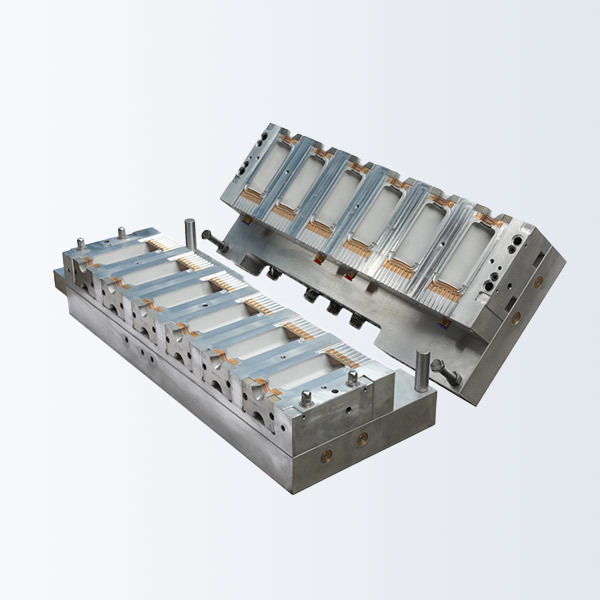

1. Introduction to OEM Teflon Injection Molds

In the world of manufacturing, achieving unparalleled precision and efficiency is paramount. **OEM Teflon injection molds** have emerged as a reliable solution for various industries, from automotive to consumer goods, due to their unique properties and versatility. This guide aims to provide a comprehensive overview of best practices for utilizing these molds effectively.

2. What is Teflon and Why Use It in Injection Molding?

Teflon, a brand name for polytetrafluoroethylene (PTFE), is a high-performance polymer known for its non-stick properties, chemical resistance, and thermal stability. In injection molding, Teflon enhances the process by reducing friction and preventing material from sticking to the mold surfaces. This results in smoother operations, reduced cycle times, and improved product quality.

3. Benefits of Using OEM Teflon Injection Molds

The adoption of OEM Teflon injection molds offers numerous advantages:

1. **Reduced Friction:** The non-stick properties of Teflon minimize friction between the mold and the injected material, leading to easier part release and less wear on the molds.

2. **Enhanced Durability:** Teflon molds exhibit superior resistance to abrasion, corrosion, and high temperatures, resulting in longer service life and reduced downtime.

3. **Improved Surface Finish:** Teflon's smooth surface ensures high-quality finishes on molded parts, reducing the need for secondary processes.

4. **Versatility:** OEM Teflon molds can be used with various materials, making them suitable for diverse applications.

5. **Cost Efficiency:** By minimizing defects and enhancing production rates, Teflon molds can lead to significant cost savings over time.

4. Best Practices for Using OEM Teflon Injection Molds

To maximize the benefits of OEM Teflon injection molds, following best practices is essential. Let's explore some key practices that can help optimize your molding operations.

4.1 Mold Preparation

Prior to initiating the injection molding process, meticulous preparation of the Teflon molds is crucial. Here are some steps to ensure proper mold preparation:

- **Cleaning:** Thoroughly clean the mold surfaces to eliminate any residues or contaminants that could affect the quality of the finished product.

- **Inspection:** Conduct a detailed inspection for any signs of wear or damage. Address any issues to prevent production interruptions.

- **Lubrication:** Use a suitable lubricant to reduce friction during the injection process, ensuring smoother operation and extending the life of the molds.

4.2 Temperature Control

Temperature plays a pivotal role in the success of injection molding with Teflon molds. Maintaining optimal temperature settings can help achieve better flow characteristics and part quality. Consider the following:

- **Optimal Melt Temperature:** Ensure the melt temperature of the material is within the recommended range for Teflon molds to facilitate proper flow and minimize degradation.

- **Mold Temperature Management:** Utilize temperature control units to maintain the mold at an ideal temperature. This helps prevent warping and ensures consistent part quality.

4.3 Pressure Adjustments

Adjusting injection pressure is critical for achieving desired results with Teflon molds. Here’s how to manage pressure effectively:

- **Initial Pressure Settings:** Start with the manufacturer’s recommended pressure settings and make incremental adjustments based on part complexity and material characteristics.

- **Monitoring Pressure:** Use pressure sensors to monitor real-time pressure levels, ensuring consistency and identifying any deviations that may require immediate attention.

4.4 Material Selection

Choosing the right material to pair with Teflon molds is essential for achieving optimal results. Consider the following factors when selecting materials:

- **Compatibility:** Ensure the selected material is compatible with Teflon to avoid reactions that could damage the mold or affect part quality.

- **Viscosity:** Understand the viscosity of the injected material, as this will impact flow and cooling rates during the injection process.

4.5 Maintenance Tips

Regular maintenance of OEM Teflon molds is vital for longevity and performance. Here are some key maintenance tips:

- **Routine Cleaning:** Implement a regular cleaning schedule to remove buildup and contaminants that can affect mold performance.

- **Regular Inspections:** Conduct periodic inspections of molds for signs of wear, particularly at high-stress areas, and address any issues promptly.

- **Proper Storage:** When not in use, store molds in a clean, dry environment to prevent damage and contamination.

5. Common Challenges and Solutions

Despite the advantages of OEM Teflon injection molds, manufacturers may encounter challenges during the injection molding process. Here are some common challenges and their solutions:

- **Product Defects:** If defects such as warping or surface blemishes occur, evaluate mold temperature and pressure settings to ensure they are within optimal ranges.

- **Difficulty in Ejection:** If parts are sticking in the mold, consider adjusting the mold design or applying a suitable mold release agent.

- **Material Degradation:** Monitor melt temperatures closely to prevent degradation of temperature-sensitive materials.

6. Case Studies: Real-World Applications

To illustrate the effectiveness of OEM Teflon injection molds, let’s examine a few case studies:

- **Case Study 1: Automotive Parts Manufacturing**

A leading automotive parts manufacturer implemented Teflon molds to produce intricate components. They reported a **30% reduction** in cycle time and a **25% decrease** in defects, significantly enhancing productivity.

- **Case Study 2: Consumer Electronics**

A consumer electronics firm utilized Teflon molds for producing casings. Their careful management of temperature and pressure led to improved surface finishes and a **40% increase** in overall production efficiency.

7. Future Trends in Teflon Injection Molding

As technology continues to evolve, several trends are emerging in Teflon injection molding:

- **Smart Manufacturing:** The integration of IoT devices will allow for real-time monitoring and adjustments during the molding process, enhancing efficiency and product quality.

- **Sustainable Practices:** As sustainability becomes a priority, manufacturers will explore eco-friendly materials compatible with Teflon molds to minimize environmental impact.

- **Advanced Coatings:** The development of advanced coatings for Teflon molds will further enhance durability and performance, reducing maintenance needs.

8. Conclusion

In conclusion, leveraging OEM Teflon injection molds effectively can significantly enhance manufacturing processes across various industries. By adhering to best practices in mold preparation, temperature control, pressure adjustments, material selection, and maintenance, manufacturers can optimize their operations for better productivity and quality. Continuous adaptation to emerging trends will ensure that businesses remain competitive in an evolving market, making the investment in Teflon molds a strategic choice for the future.

RELATED NEWS