Unlocking Precision: The Advantages of China Insert Injection Mold

Time:

2025-03-01

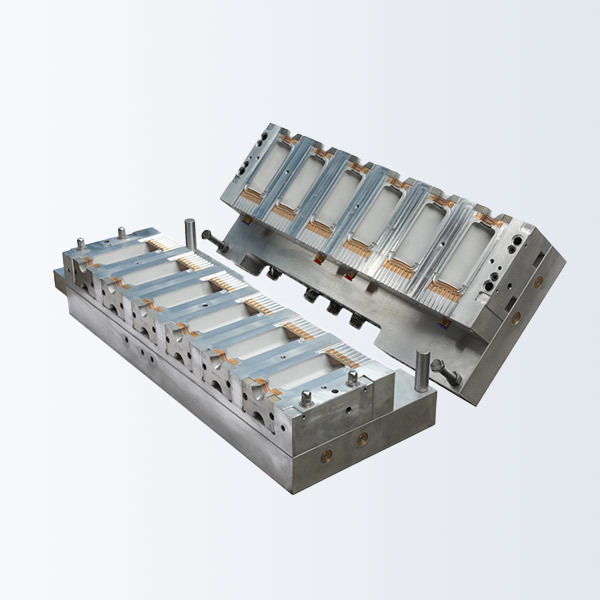

Insert injection molding is a specialized form of injection molding that enables manufacturers to insert materials—such as metal or plastic—into a mold to create complex parts. This method allows for the creation of intricate designs that are often challenging to achieve with traditional molding techniques. By using **insert injection molds**, manufacturers can produce high-quality products with superior dimensional accuracy.

Key Advantages of China Insert Injection Mold

When considering China Insert Injection Molds, it’s essential to comprehend the multitude of advantages they offer. Let’s delve deeper into these benefits:

Enhanced Precision and Quality

One of the primary advantages of utilizing China Insert Injection Molds is the **enhanced precision** they provide. These molds are designed using advanced technologies that ensure strict tolerances, resulting in high-quality products. The precision achieved through this method minimizes the need for additional finishing processes, thereby reducing production time and costs.

Cost-Effectiveness in Production

Cost-effectiveness is a crucial factor for any manufacturing business. China Insert Injection Molds offer **affordable production** solutions without compromising on quality. The use of advanced materials and techniques in mold manufacturing leads to lower material waste and reduced cycle times. Consequently, businesses can enjoy a higher return on investment through cost savings in labor and resources.

Increased Production Efficiency

The efficiency of the manufacturing process is paramount to meeting market demands. With China Insert Injection Molds, manufacturers can achieve **faster production cycles**. These molds allow for rapid setup and easy integration into existing production lines, enabling companies to increase their output without significant additional investments. Enhanced efficiency leads to quicker turnaround times, allowing businesses to remain competitive in a fast-paced market.

Diverse Material Options

China Insert Injection Molds provide access to a wide range of **material options**. From thermoplastics to elastomers and metals, manufacturers can choose the most suitable materials for their specific applications. This flexibility enables the production of parts with varying mechanical properties, surface finishes, and aesthetic qualities, catering to diverse industry needs.

Applications of China Insert Injection Molds

The versatility of China Insert Injection Molds positions them as a preferred choice across several industries. Some of the most common applications include:

1. **Automotive Components**: High-precision parts for vehicles, including dashboards and structural components.

2. **Consumer Electronics**: Enclosures and internal components for devices like smartphones and tablets.

3. **Medical Devices**: Production of intricate parts for medical equipment with stringent quality requirements.

4. **Home Appliances**: Molding parts for appliances, ensuring durability and aesthetic appeal.

5. **Packaging**: Custom molds for packaging solutions that require specific designs and material properties.

Choosing a Reliable Manufacturer

Selecting the right manufacturer for China Insert Injection Molds is crucial to ensuring quality and reliability. Here are some factors to consider:

- **Experience and Expertise**: Look for manufacturers with a proven track record in the industry and experience in producing insert injection molds.

- **Quality Assurance**: Ensure the manufacturer follows strict quality control measures and has certifications that guarantee the quality of their products.

- **Customization Capabilities**: A good manufacturer should be able to customize molds according to your specific requirements.

- **Customer Support**: Choose a manufacturer that offers excellent customer service and supports you throughout the production process.

The Future of Injection Molding Technology

As technology continues to advance, the future of injection molding looks promising. Innovations such as **3D printing integration**, automation, and the use of smart technologies are set to revolutionize the industry. By staying informed about these trends, manufacturers can adopt strategies that enhance their production capabilities further, ensuring they remain competitive in a rapidly evolving market.

In conclusion, China Insert Injection Molds present numerous advantages that can significantly enhance manufacturing processes across various industries. With their ability to produce high-precision parts efficiently and cost-effectively, these molds serve as a valuable asset for businesses striving for excellence. By understanding the benefits and applications of this technology, manufacturers can make informed decisions that align with their operational goals. Embracing China Insert Injection Molding technology could very well be the key to unlocking precision and creating superior products in the competitive marketplace.

RELATED NEWS