Understanding Durable Shampoo Bottle Blow Molding: A Guide to Quality and Efficiency

Time:

2025-04-20

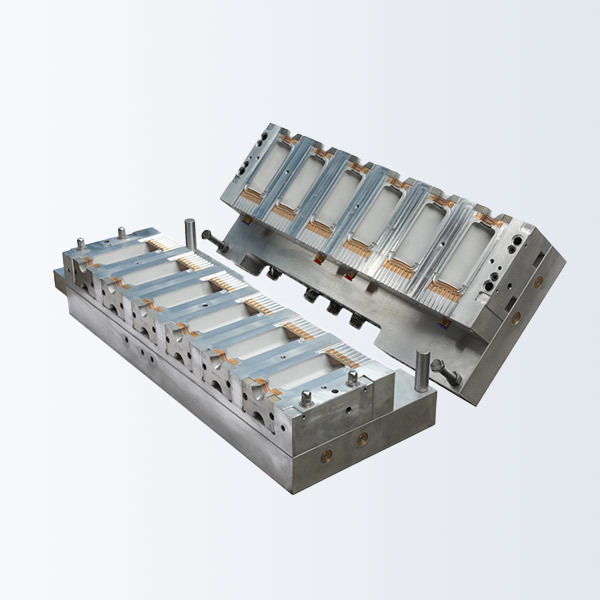

In the realm of manufacturing and processing machinery, the production of durable shampoo bottle blow molds is a critical area of focus. Blow molding is a widely used manufacturing process for creating hollow plastic products, and it is particularly advantageous for producing bottles that require both strength and flexibility. This method involves inflating a heated plastic tube, known as a parison, into the desired shape of the mold. As a result, manufacturers can create shampoo bottles that not only meet consumer expectations for design but also stand up to the rigors of use and transport.

One of the primary benefits of using blow molding for shampoo bottle production is its ability to create lightweight yet durable containers. The materials commonly used in blow molding, such as polyethylene and polypropylene, are known for their resilience and resistance to impact. This durability is essential in the personal care industry, where products are often subjected to various environmental factors, including moisture, temperature variations, and handling during shipping and storage.

Furthermore, the design flexibility offered by blow molding technology allows manufacturers to create bottles in various shapes and sizes. This versatility means that brands can differentiate themselves on the shelf with unique bottle designs while maintaining the structural integrity required for safe storage of their products. Additionally, blow molding can accommodate features such as ergonomic grips and dispensing mechanisms, enhancing the user experience.

Another key aspect of durable shampoo bottle blow molds is the efficiency of the manufacturing process. Once the mold design is finalized, the blow molding process can produce large quantities of bottles in a relatively short time frame. This efficiency not only reduces production costs but also helps meet the growing demands of the market. Manufacturers can quickly respond to trends in the personal care industry, ensuring that products are available when consumers need them.

Moreover, the focus on sustainability in recent years has prompted many manufacturers to explore eco-friendly options in their blow molding processes. Innovations in material science have led to the development of biodegradable plastics and recycled materials, allowing brands to produce environmentally conscious products without compromising on quality or durability.

In conclusion, the production of durable shampoo bottle blow molds is a vital component of the personal care industry. By leveraging blow molding technology, manufacturers can create lightweight, resilient bottles that meet the demands of modern consumers. The combination of design flexibility, production efficiency, and the potential for sustainable practices makes blow molding a preferred choice for producing high-quality shampoo bottles. Understanding these aspects can help businesses in the manufacturing sector optimize their processes and better serve their clients.

One of the primary benefits of using blow molding for shampoo bottle production is its ability to create lightweight yet durable containers. The materials commonly used in blow molding, such as polyethylene and polypropylene, are known for their resilience and resistance to impact. This durability is essential in the personal care industry, where products are often subjected to various environmental factors, including moisture, temperature variations, and handling during shipping and storage.

Furthermore, the design flexibility offered by blow molding technology allows manufacturers to create bottles in various shapes and sizes. This versatility means that brands can differentiate themselves on the shelf with unique bottle designs while maintaining the structural integrity required for safe storage of their products. Additionally, blow molding can accommodate features such as ergonomic grips and dispensing mechanisms, enhancing the user experience.

Another key aspect of durable shampoo bottle blow molds is the efficiency of the manufacturing process. Once the mold design is finalized, the blow molding process can produce large quantities of bottles in a relatively short time frame. This efficiency not only reduces production costs but also helps meet the growing demands of the market. Manufacturers can quickly respond to trends in the personal care industry, ensuring that products are available when consumers need them.

Moreover, the focus on sustainability in recent years has prompted many manufacturers to explore eco-friendly options in their blow molding processes. Innovations in material science have led to the development of biodegradable plastics and recycled materials, allowing brands to produce environmentally conscious products without compromising on quality or durability.

In conclusion, the production of durable shampoo bottle blow molds is a vital component of the personal care industry. By leveraging blow molding technology, manufacturers can create lightweight, resilient bottles that meet the demands of modern consumers. The combination of design flexibility, production efficiency, and the potential for sustainable practices makes blow molding a preferred choice for producing high-quality shampoo bottles. Understanding these aspects can help businesses in the manufacturing sector optimize their processes and better serve their clients.

RELATED NEWS