Enhancing Operational Efficiency with the Latest 4L Mobil Bottle Blow Mold

Time:

2025-04-17

Enhancing Operational Efficiency with the Latest 4L Mobil Bottle Blow Mold

In the ever-evolving landscape of manufacturing, the demand for innovative solutions to enhance operational efficiency is at an all-time high. One of the most significant advancements in this field is the introduction of the latest 4L Mobil Bottle Blow Mold. This article delves deep into how this cutting-edge technology can transform your production processes, resulting in increased productivity, reduced costs, and improved product quality.

Table of Contents

- Understanding Bottle Blow Molding

- What is the 4L Mobil Bottle Blow Mold?

- Key Features of the 4L Mobil Bottle Blow Mold

- Benefits of Using the 4L Mobil Bottle Blow Mold

- Operational Efficiency Improvements

- Applications and Industries Utilizing 4L Mobil Bottle Blow Molds

- Maintenance and Sustainability of the 4L Mobil Bottle Blow Mold

- Future Trends in Bottle Blow Molding Technology

- Conclusion

- FAQs

Understanding Bottle Blow Molding

Bottle blow molding is a manufacturing process used to create hollow plastic objects, primarily bottles. This technique involves heating plastic materials until they become pliable, after which they are molded into specific shapes using a mold. The blow molding method is widely appreciated due to its efficiency in producing large quantities of items with uniform quality and minimal waste.

The process typically consists of three main stages: extrusion, inflation, and cooling. By understanding these stages, manufacturers can optimize each segment for better output.

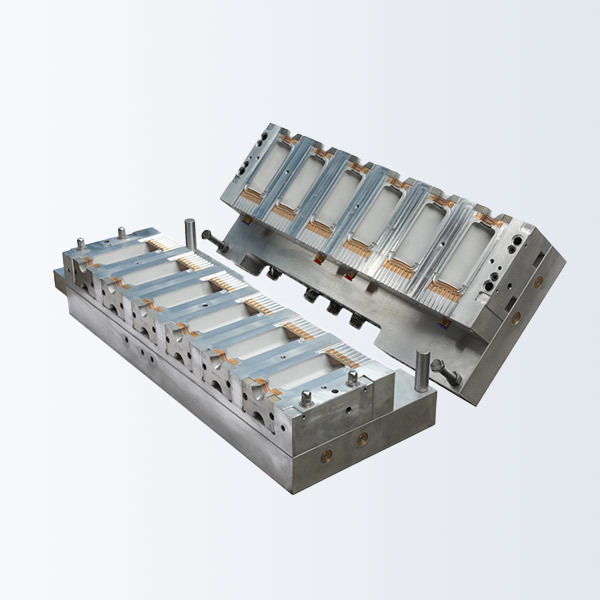

What is the 4L Mobil Bottle Blow Mold?

The **4L Mobil Bottle Blow Mold** refers to a specialized mold designed for producing 4-liter plastic bottles. This innovative tool is engineered with precision to enhance the blow molding process, ensuring optimal performance and product quality. Its design allows for seamless integration with existing machinery while maximizing production efficiency.

Design and Construction

The design of the 4L Mobil Bottle Blow Mold leverages advanced materials and technologies to withstand high temperatures and pressures during the molding process. It often incorporates features such as:

- **Streamlined airflow channels** for improved cooling

- **Enhanced durability** to minimize wear and tear

- **Precision-engineered cavities** to ensure uniformity in bottle shape and size

Key Features of the 4L Mobil Bottle Blow Mold

The 4L Mobil Bottle Blow Mold is packed with features that set it apart from traditional molding options. Key features include:

1. High Production Capacity

Designed to handle large volumes, the 4L mold allows manufacturers to produce a significant number of bottles in a shorter time frame, thereby increasing overall productivity.

2. Energy Efficiency

With a focus on reducing energy consumption, this blow mold utilizes technology that optimizes thermal efficiency during the heating and cooling processes.

3. Versatile Compatibility

The mold is compatible with various plastic materials, including PET, HDPE, and PVC, offering manufacturers the flexibility to choose the best material for their specific needs.

4. User-Friendly Design

The intuitive design simplifies the setup and maintenance processes, allowing operators to focus on production rather than troubleshooting mold issues.

Benefits of Using the 4L Mobil Bottle Blow Mold

Adopting the 4L Mobil Bottle Blow Mold comes with numerous advantages that can significantly impact a manufacturing operation:

1. Cost Savings

By increasing production efficiency and reducing energy consumption, manufacturers can realize substantial cost savings. The durability of the mold also contributes to lower replacement costs over time.

2. Improved Product Quality

The precision engineering of the 4L mold ensures that each bottle produced meets high-quality standards, reducing the likelihood of defects and waste.

3. Faster Time-to-Market

With its high production capacity, manufacturers can quickly respond to market demands, ensuring that they are always one step ahead of competitors.

4. Enhanced Sustainability

By minimizing material waste and energy use, the 4L Mobil Bottle Blow Mold aligns with sustainable manufacturing practices, appealing to environmentally conscious consumers and businesses.

Operational Efficiency Improvements

Implementing the latest technology in blow molding has proven to significantly enhance operational efficiency across various sectors. Key improvements include:

1. Streamlined Production Processes

The advanced features of the 4L Mobil Bottle Blow Mold lead to reduced cycle times and streamlined production processes. This efficiency allows manufacturers to allocate resources more effectively and meet tight deadlines.

2. Reduction in Labor Costs

Automated features in the 4L mold reduce the need for manual intervention, allowing manufacturers to operate with fewer staff while maintaining productivity levels.

3. Enhanced Monitoring and Control

Modern blow molds often come equipped with smart technology that enables real-time monitoring and adjustments, ensuring consistent quality and minimizing downtime.

Applications and Industries Utilizing 4L Mobil Bottle Blow Molds

The versatility of the 4L Mobil Bottle Blow Mold makes it suitable for a wide range of applications across various industries:

1. Beverage Industry

From soft drinks to water, the beverage industry benefits greatly from efficient bottle production, which is essential for meeting consumer demands.

2. Personal Care Products

Manufacturers of shampoos, conditioners, and lotions leverage the 4L mold for its ability to create attractive and functional packaging.

3. Household Cleaning Products

The durability and design flexibility of the 4L mold make it an ideal choice for producing bottles for household cleaning supplies.

4. Chemical Industry

In the chemical sector, the 4L Mobil Bottle Blow Mold offers safety and practicality for packaging potentially hazardous materials.

Maintenance and Sustainability of the 4L Mobil Bottle Blow Mold

To fully realize the benefits of the 4L Mobil Bottle Blow Mold, ongoing maintenance and a commitment to sustainability are crucial:

1. Regular Maintenance Practices

Implementing a regular maintenance schedule ensures that the blow molds operate efficiently and last longer. Key practices include:

- Routine inspections for wear and tear

- Cleaning cooling channels and cavities

- Lubricating moving parts to prevent friction

2. Emphasizing Sustainable Practices

Emphasizing sustainable practices, such as recycling scrap plastic and reducing energy consumption, aligns with global initiatives towards environmental responsibility and enhances a company’s reputation.

Future Trends in Bottle Blow Molding Technology

The future of bottle blow molding looks promising with emerging trends that enhance production capabilities and sustainability:

1. Smart Technology Integration

Emerging technologies like IoT and AI are likely to play a significant role in monitoring production processes, predictive maintenance, and enhancing product quality.

2. Biodegradable Materials

As environmental concerns grow, the industry is shifting toward using biodegradable materials, fostering innovation in mold design and material compatibility.

3. Customization and Personalization

With consumer preferences evolving, there's a growing demand for customizable packaging solutions. Future molds will likely accommodate unique designs and variations.

Conclusion

The 4L Mobil Bottle Blow Mold represents a significant advancement in the plastic molding industry, emphasizing operational efficiency, cost-effectiveness, and sustainability. By adopting this innovative technology, manufacturers can improve production processes, reduce costs, and meet the growing demands of various industries. As we move forward, embracing advanced technologies and sustainable practices will be crucial for maintaining a competitive edge in this dynamic market.

FAQs

1. What materials can the 4L Mobil Bottle Blow Mold work with?

The 4L Mobil Bottle Blow Mold is compatible with various materials, including PET, HDPE, and PVC.

2. How does the 4L mold improve energy efficiency?

The mold utilizes advanced insulation and airflow management to minimize energy consumption during the heating and cooling processes.

3. What are the typical cycle times for producing 4-liter bottles?

Cycle times vary based on machine setup and material, but the 4L mold is designed for rapid production, often completing a cycle in a matter of minutes.

4. How can manufacturers ensure product quality with the 4L mold?

Regular maintenance and real-time monitoring technologies help maintain quality standards and reduce defects during production.

5. Is training required to operate the 4L Mobil Bottle Blow Mold?

While the mold is designed for user-friendliness, some training may be beneficial for operators to fully utilize its features and ensure safety during operation.

RELATED NEWS