Exploring the Benefits of Blow Molding for 200mL Shampoo Bottles

Time:

2025-04-15

Exploring the Benefits of Blow Molding for 200mL Shampoo Bottles

Table of Contents

- 1. Introduction to Blow Molding

- 2. What is Blow Molding?

- 3. Advantages of Blow Molding for Shampoo Bottles

- 3.1 Cost-Effectiveness

- 3.2 Design Flexibility

- 3.3 Material Utilization

- 3.4 Production Speed

- 3.5 Lightweight Design

- 4. Applications in Personal Care Industry

- 5. Sustainability Aspects of Blow Molding

- 6. The Future of Blow Molding in Packaging

- 7. Frequently Asked Questions (FAQs)

- 8. Conclusion

1. Introduction to Blow Molding

In today's competitive market, the choice of packaging plays a crucial role in product marketing and consumer satisfaction. Among various manufacturing processes, blow molding stands out for its efficiency and versatility, particularly in producing containers like 200mL shampoo bottles. This article investigates the benefits of blow molding, highlighting its relevance in modern packaging solutions for personal care products.

2. What is Blow Molding?

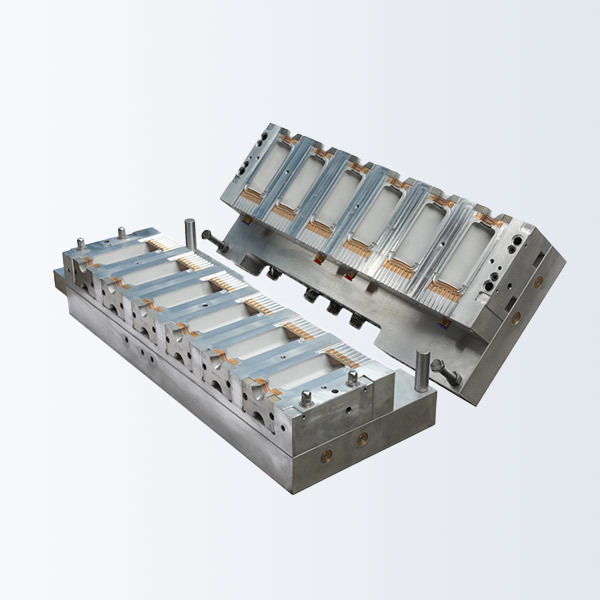

Blow molding is a manufacturing process used primarily to create hollow plastic parts. It involves heating and inflating a plastic tube known as a parison, which is then shaped into the desired form using a mold. This method is particularly effective for producing uniform, lightweight, and sturdy products. In the context of shampoo bottles, blow molding enables the production of various designs and sizes, catering specifically to market demands.

3. Advantages of Blow Molding for Shampoo Bottles

Blow molding offers numerous advantages when it comes to the production of 200mL shampoo bottles. Understanding these benefits can help brands make informed decisions about their packaging solutions.

3.1 Cost-Effectiveness

One of the most significant benefits of blow molding is its cost-effectiveness. The process allows manufacturers to produce large quantities of bottles at a lower cost per unit. The efficiency of the blow molding process reduces labor and material expenses, enabling brands to keep their production costs down. This is especially important in the competitive personal care market, where cost efficiency can directly influence pricing strategies.

3.2 Design Flexibility

Blow molding provides exceptional design flexibility, allowing manufacturers to create customized bottles that meet specific customer needs. From unique shapes to intricate surface designs, brands can differentiate their products in the market. The ability to incorporate features such as ergonomic grips or aesthetically pleasing shapes adds value to the product and enhances the consumer experience.

3.3 Material Utilization

Blow molding maximizes material utilization, reducing waste during the manufacturing process. The process typically uses thermoplastics such as polyethylene and polypropylene, which can be recycled. This focus on efficient material use not only lowers production costs but also aligns with sustainability goals, appealing to environmentally-conscious consumers.

3.4 Production Speed

The speed at which blow molding can produce bottles is another critical advantage. High-speed production lines can manufacture millions of bottles annually, ensuring that brands can meet high demand without compromising quality. This rapid production capability is essential for large companies that require consistent and timely packaging solutions.

3.5 Lightweight Design

Blow molding creates lightweight bottles that are easier to handle and transport. This feature not only reduces shipping costs but also enhances user convenience. Additionally, lighter bottles require less material, further contributing to sustainability efforts. Brands that prioritize lightweight packaging can appeal to consumers seeking eco-friendly options without sacrificing functionality.

4. Applications in Personal Care Industry

The personal care industry, particularly in the production of shampoo and other hair care products, has greatly benefited from blow molding technology. Companies can create bottles that effectively showcase their branding while ensuring that the product remains safe and secure. The ability to produce various designs caters to different segments of the market, from premium to budget-friendly options.

5. Sustainability Aspects of Blow Molding

As consumers become increasingly aware of environmental issues, sustainable packaging solutions are in high demand. Blow molding fits perfectly within the sustainability framework by utilizing recyclable materials and minimizing waste. Brands adopting blow molding can enhance their eco-friendly image, appealing to a growing segment of environmentally-conscious consumers.

6. The Future of Blow Molding in Packaging

The future of blow molding looks promising as technology continues to advance. Innovations in materials and processes will enhance production efficiency and sustainability. Brands that invest in the latest blow molding technologies can stay competitive and meet evolving consumer demands. Additionally, as regulations around plastic usage become stricter, blow molding's adaptability will enable companies to conform to new standards while maintaining high-quality packaging.

7. Frequently Asked Questions (FAQs)

What types of materials are used in blow molding?

Blow molding primarily utilizes thermoplastics, such as polyethylene, polypropylene, and polyvinyl chloride (PVC). These materials are chosen for their durability, flexibility, and recyclability.

How does blow molding compare to other molding processes?

Blow molding is particularly advantageous for producing hollow objects like bottles, whereas injection molding is more suitable for solid products. Blow molding offers quicker production times and better material efficiency for hollow items.

Can blow molded bottles be customized?

Yes, blow molding allows for significant customization, including shapes, sizes, and surface texture. This flexibility is beneficial for brands looking to differentiate their products in the market.

Is blow molding environmentally friendly?

Blow molding can be environmentally friendly due to its efficient use of materials and the ability to use recyclable plastics. Brands focused on sustainability often prefer this method for their packaging needs.

How long does it take to produce blow molded bottles?

The production time for blow molded bottles can vary based on the complexity of the design and the efficiency of the machinery. However, high-speed blow molding lines can produce thousands of bottles per hour.

8. Conclusion

In conclusion, the benefits of blow molding for 200mL shampoo bottles are extensive and impactful. From cost-effectiveness and design flexibility to sustainability and rapid production capabilities, blow molding stands as a superior choice for brands in the personal care industry. As consumer preferences evolve, adopting innovative packaging solutions like blow molding will be crucial for maintaining a competitive edge. By prioritizing this technology, brands can not only enhance their product appeal but also contribute positively to the environment, ultimately fostering a sustainable future for the packaging industry.

RELATED NEWS