Unlocking the Secrets of the Best Prototype Plastic Molds

Time:

2025-03-03

Unlocking the Secrets of the Best Prototype Plastic Molds

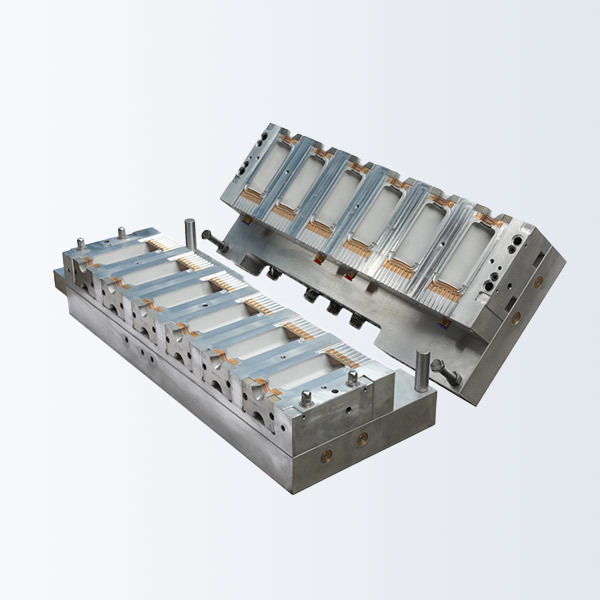

In the fast-evolving landscape of manufacturing, the demand for high-quality plastic products is on the rise. **Prototype plastic molds** play a crucial role in this sector, serving as the foundation for creating precise and efficient prototypes. This article delves into the intricacies of prototype plastic molds, providing insights that can help businesses streamline their production processes and enhance product quality. From understanding different types of molds to exploring advanced technologies in mold-making, we cover it all.

Table of Contents

- What Are Prototype Plastic Molds?

- The Importance of Prototype Molding in Manufacturing

- Types of Plastic Molds Used in Prototyping

- The Mold Design Process: Step-by-Step

- Materials Used in Mold Making: Choosing the Right One

- Advanced Technologies in Prototype Plastic Molding

- Emerging Trends in the Plastic Molding Industry

- Common Challenges in Prototype Mold Making and Solutions

- Frequently Asked Questions (FAQs)

What Are Prototype Plastic Molds?

Prototype plastic molds are specialized tools used to produce plastic parts in a controlled environment. These molds are essential for testing and validating designs before moving to full-scale production. By using prototype molds, manufacturers can quickly iterate on designs, ensure functionality, and minimize costly errors down the line. They are typically made from various materials, including metal and plastic, depending on the intended use and material properties required.

The Importance of Prototype Molding in Manufacturing

Prototype molding is not just an optional step; it is a critical component of the product development lifecycle. The **importance of prototype molding** lies in several key factors:

- Design Validation: Prototypes allow for real-world testing of designs, ensuring they meet specifications and customer expectations.

- Cost Efficiency: Identifying design flaws early reduces costs associated with material waste and rework during full production.

- Speed to Market: Rapid prototyping can significantly shorten the time it takes to bring a product to market, providing a competitive advantage.

Types of Plastic Molds Used in Prototyping

Understanding the different types of plastic molds is crucial for selecting the right one for your project. Here are some of the most common types:

1. Injection Molds

Injection molding is the most prevalent method for producing plastic parts. It involves injecting molten plastic into a mold cavity, where it cools and solidifies. This method is ideal for high-volume production and complex designs.

2. Blow Molds

Blow molding is used primarily for hollow plastic parts, such as bottles. The process involves inflating a heated plastic tube into a mold to form the desired shape.

3. Compression Molds

Compression molding is typically used for thermosetting plastics. It involves placing a plastic material in a heated mold cavity, which is then closed to create the desired shape.

4. Rotational Molds

Rotational molding is a process for producing large, hollow parts. It involves rotating a mold while heating it, allowing the plastic to coat the mold's interior surface.

5. 3D Printed Molds

With advancements in 3D printing technology, creating molds directly from a computer-aided design (CAD) file has become increasingly popular. This method allows for rapid prototyping and customization.

The Mold Design Process: Step-by-Step

The mold design process is crucial in ensuring that the final product meets all specifications. Here’s a comprehensive look at the stages of mold design:

1. Conceptualization

Start with a concept and detailed sketches of the product. Collaborate with designers and engineers to refine your ideas.

2. CAD Modeling

Create a computer-aided design (CAD) model that accurately represents the product. This model serves as the blueprint for the mold.

3. Mold Flow Analysis

Conduct a mold flow analysis to identify potential issues in the molding process, such as air traps or cooling inefficiencies.

4. Prototype Development

Develop a prototype mold based on the CAD model. This step includes iterations of testing and refinement.

5. Final Design Approval

Review the prototype with stakeholders and obtain final approval before proceeding to full-scale production.

Materials Used in Mold Making: Choosing the Right One

Selecting the right material for mold making is vital for achieving the desired results. Here are some common materials used in creating molds:

1. Steel

Steel molds are durable and can withstand high pressures, making them ideal for large production runs.

2. Aluminum

Aluminum molds are lighter and easier to machine than steel, making them suitable for shorter production runs and prototyping.

3. Silicone

Silicone molds are flexible and can capture fine details, making them perfect for intricate designs or low-volume production.

4. Composite Materials

Composite materials offer a balance of strength and weight, providing an alternative for specialized applications.

Advanced Technologies in Prototype Plastic Molding

The world of prototype plastic molding is evolving with the introduction of advanced technologies that enhance efficiency and precision. Notable advancements include:

1. 3D Printing

Utilizing 3D printing for mold creation allows for faster turnaround times and the ability to produce complex geometries that traditional methods may not achieve.

2. Digital Twin Technology

Digital twins simulate the molding process, enabling manufacturers to predict outcomes and optimize designs before production.

3. Automation and Robotics

Automation in mold-making processes reduces labor costs and enhances consistency, leading to higher quality products.

Emerging Trends in the Plastic Molding Industry

The plastic molding industry is continually evolving, and staying updated with the latest trends is crucial for manufacturers. Key trends include:

1. Sustainability Practices

With increasing environmental concerns, many companies are adopting sustainable practices, such as using recycled materials and reducing waste.

2. Customization and Personalization

Customers are seeking more personalized products. Manufacturers can now offer customized solutions through advanced molding technologies.

3. Integration of IoT

The Internet of Things (IoT) is transforming the industry by enabling real-time monitoring and data collection throughout the molding process, leading to improved efficiency.

Common Challenges in Prototype Mold Making and Solutions

Despite advancements in technology, challenges in mold making persist. Here are some common issues and their solutions:

1. Design Flaws

Design flaws can lead to significant problems in the molding process. Conduct thorough reviews and simulations to identify potential flaws early.

2. Material Selection

Choosing the wrong material can compromise the mold's performance. Always consider the product's end-use and environmental factors when selecting materials.

3. Cost Overruns

Unexpected costs can arise during production. To combat this, maintain a detailed budget and timeline throughout the design and manufacturing phases.

Frequently Asked Questions (FAQs)

1. What is the purpose of prototype plastic molds?

Prototype plastic molds are essential for creating test versions of products, allowing manufacturers to refine designs and functions before mass production.

2. How long does the mold-making process take?

The mold-making process can take anywhere from a few weeks to several months, depending on complexity and material selection.

3. What materials are commonly used in prototype molds?

Common materials include steel, aluminum, silicone, and composite materials, each chosen for specific project requirements.

4. How can I ensure the quality of my prototype molds?

Conduct thorough testing, use quality materials, and collaborate closely with experienced mold designers and manufacturers to ensure high-quality molds.

5. What are the benefits of 3D printing in mold making?

3D printing provides faster production times, greater design flexibility, and the ability to create complex geometries that traditional methods cannot easily achieve.

Conclusion

In conclusion, understanding the nuances of **prototype plastic molds** is essential for any business looking to excel in the manufacturing sector. By leveraging the right materials, technologies, and processes, companies can create high-quality prototypes that lead to successful products. As the industry continues to evolve, staying informed about trends and advancements will ensure continued success in this competitive landscape. Embrace the power of effective mold design and production to unlock the full potential of your plastic products.

RELATED NEWS