Essential Insights for Buying Foam Injection Molds in the Manufacturing Industry

Time:

2025-03-14

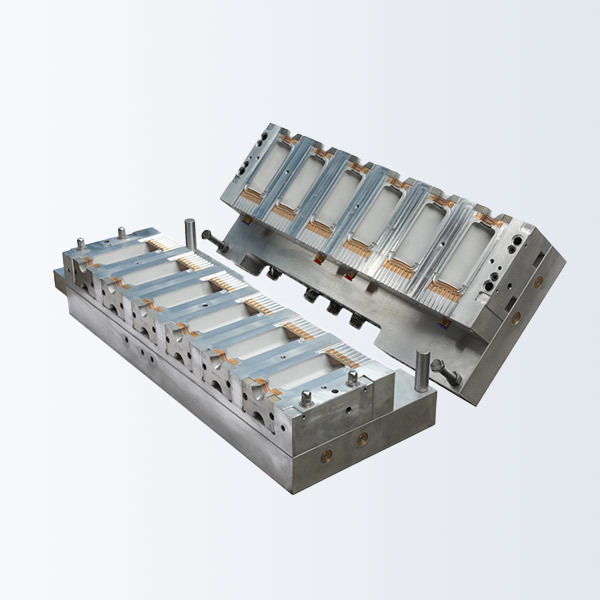

When considering the purchase of foam injection molds, it is crucial to understand their significance in the manufacturing process, particularly in the realm of plastic forming. Foam injection molding is a specialized technique that allows for the production of lightweight, highly durable parts with exceptional insulation properties. As such, it has a wide array of applications, from automotive components to consumer goods. Here are some essential insights to guide you in making an informed decision about buying foam injection molds.

Firstly, identify the specific needs of your manufacturing process. Foam injection molds come in various designs and configurations tailored for different applications. Assess the volume of production required and the complexity of the parts to be produced. A thorough understanding of your project requirements will help you select a mold that maximizes efficiency and meets your quality standards.

Secondly, the material of the mold itself is a critical consideration. The durability and longevity of the mold can greatly affect production costs over time. Typically, molds are made from steel, aluminum, or other advanced materials. Steel molds offer superior durability and are ideal for high-volume production, while aluminum molds are lighter and more economical for lower production runs. Understanding the trade-offs between these materials will aid you in making the right choice based on your specific needs and budget.

Another important factor is the design and engineering capabilities of the mold manufacturer. It is advisable to collaborate with a manufacturer who has a strong track record in foam injection molding and can provide custom solutions tailored to your requirements. Their expertise can ensure that the molds are optimized for performance, reducing the risk of defects and rework during production.

Additionally, consider the technological advancements in foam injection molding. Investing in molds equipped with the latest technology can improve efficiency and reduce cycle times, leading to significant cost savings in the long run. Manufacturers that incorporate automation and advanced monitoring systems into their molds can offer a competitive edge, making it easier to maintain consistent quality across production runs.

Lastly, don't underestimate the importance of after-sales support and service. A reputable manufacturer should offer comprehensive support, including maintenance, troubleshooting, and potential upgrades. Establishing a good relationship with your vendor can help ensure a smoother operational process and mitigate any issues that may arise post-purchase.

In conclusion, buying foam injection molds is a significant investment that can enhance your manufacturing capabilities. By understanding your needs, selecting the right materials, and partnering with a knowledgeable manufacturer, you can ensure that your investment yields the desired results while optimizing production efficiency.

RELATED NEWS